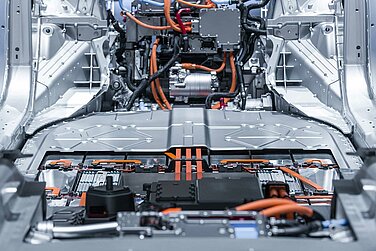

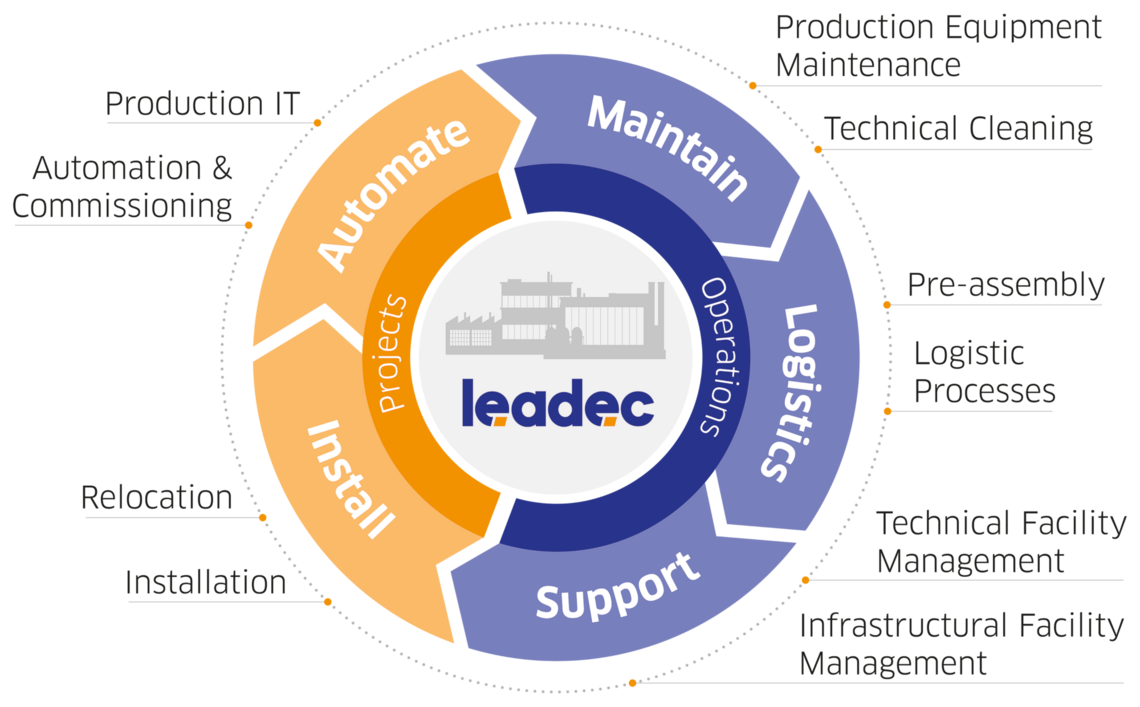

The world’s automotive factories are our home. We have helped to plan or automated many of the major OEMs’ plants and have been maintaining them for years. Whether internal combustion engine or electric motor, classic powertrain or battery assembly – we are there with our expertise.

Battery production is a new territory for many OEMs. Leadec has been gaining experience in this field for years and has proven its competence. For a German premium brand, we have planned and set up the automation and screwdriving systems in the high-voltage battery assembly. Because complex assembly processes are the core element in the modern production of battery components or even entire systems. Batteries are very sensitive to shocks. Both during assembly and handling, care must be taken to ensure a "low-shock" process.

Once the battery factory is in place, we are permanently on site with our industrial services. To ensure the battery assembly’s quality, we ensure the complete plant and equipment’s availability. Our service includes production equipment maintenance for assembly lines on which batteries are assembled and the associated automated guided vehicles.